Demonstration trials in Brazil, repeated over 5 locations in 3 states over two years, showed a consistent increase in yield (+ 8-15%), price for quality (+ 2-14% ) and net revenue (+ 374-2223 USD/ha) in potato. This was achieved by offering the grower a balanced nutrition programme based on potassium nitrate, applied either as granular fertilizer (Nutrisystem®, the SQM VITAS brand of Qrop®), or wsNPK (Dripsol®, the SQM VITAS brand of Ultrasol®), through pivot irrigation.

This is an excellent example of the benefit of potassium nitrate in granular and wsNPK side dressing, for field adjustment of the N:K ratio considering crop stage requirement, increasing the percentage of nitric nitrogen (N-NO3) in the total N applied, and reducing yield loss due to excessive chloride uptake by the plant.

Table 1. Location and details of five trials conducted in 2018 and 2019 in Brazil by SQM VITAS.

The development of technical proposals focused on efficiency, profitability and sustainable development of production.

Custom designed NPK formulae were included in a nutrition programme fitting the crop stage requirements, to increase yield and tuber caliber and quality by optimizing the efficiency of nutrient uptake by the plant.

The nutrition programme was adapted to fit the local growing conditions, farm economy and cropping systems.

Figure 1. Total tuber weight from 1 linear meter (kg/m) per nutritional programme. Cultivar Ágata, 70 days after planting (Trial 3).

The overarching aim for the project was to improve the current farmer practice on the following aspects:

- Reduce the application of chloride by substitution of KCl by KNO3,

- Increase the proportion of N-NO3 in the total N, to reduce risk of excess chloride uptake, and improve cation uptake. Inclusion of KNO3 (potassium nitrate) in the programme, allows for reduced amounts of low-quality nitrogen sources supplying nitrogen forms with high risk of loss to the environment after volatilization (N-NH2 and N- NH4),

- Increase availability of potassium during the critical crop stages, by tuning the N:K ratio according to crop requirement per stage.

Table 2. SQM Vitas portfolio serving as a tool-box to design balanced nutrient programmes for potato growers.

The trials were conducted on farmers fields (Table 1). A designated part of the area cultivated with the same cultivar of potato under identical crop management was fertilized with the SQM VITAS nutrition programme, and was harvested separately from the surface under current farmers practice (FP) to assess difference in yield and distribution of tubers in different caliber classes. An economic analysis was performed based on productivity and tuber quality through price distinction. During the season, samples of 1 linear meter were assessed in order to record the number of tubers, size and weight as standard part of the field trial protocol (Figures 1 and 2). This is routine for the agronomist team of SQM VITAS.

If the results are not according to expectation, the nutrient programme can be adapted to improve the final yield. For example, another timing of the next application, a change in N:K ratio or balance of nitrogen sources can be suggested.

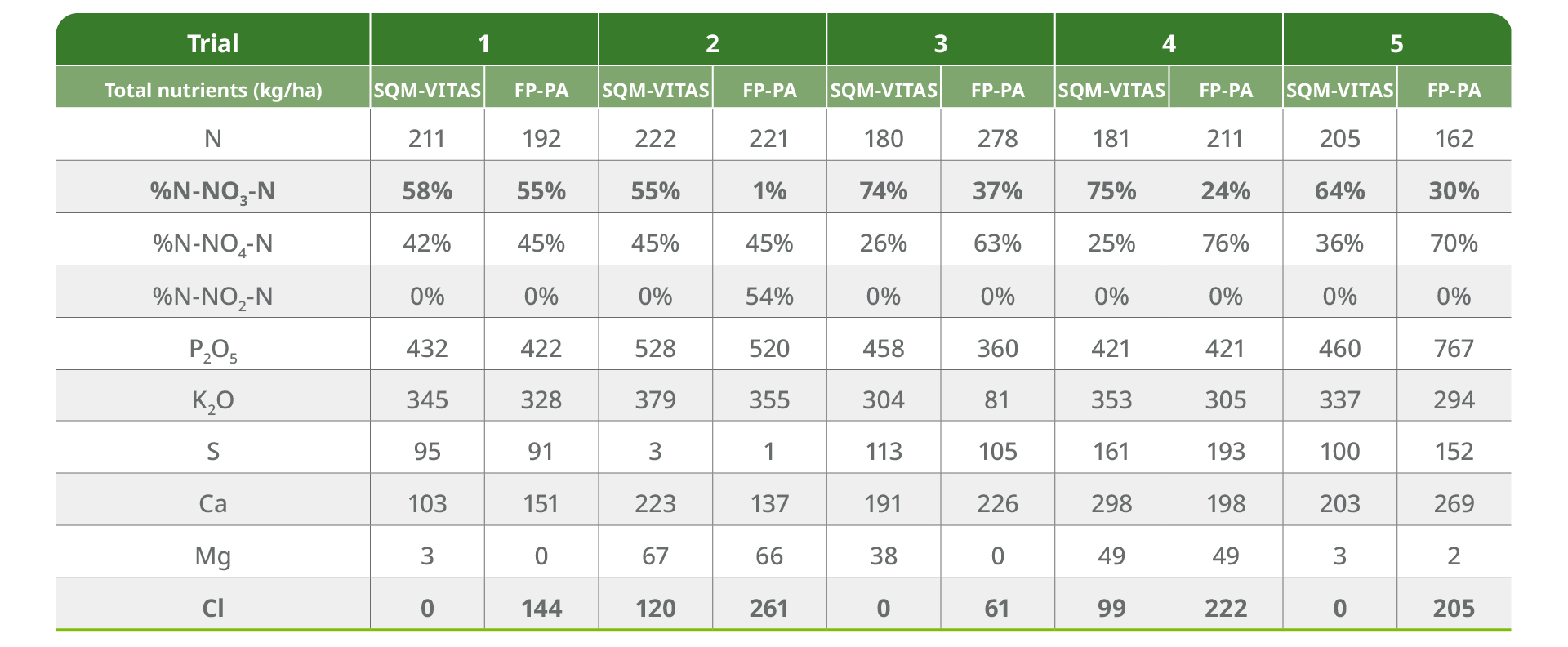

Table 3. Applied nutrients/ha in the five Brazilian trials. FP= farmers practice.

Figure 2. Tuber size and linear meter yield at tuber filling of the cultivar Frito-Lay in the SQM Vitas nutrient programme ("SVB") and the farmers programme ("Teste") (Trial 4).

Figure 3. Harvest of the cultivar Cupido, fertilized following the SQM VITAS programme, shows uniform tuber size (Trial 5).

Potassium nitrate was applied in side- or base dressing with a range of available granular fertilizers, the SQM VITAS Brazil equivalent of the Qrop®-brands: Nutrisystem Inicial 42, Nutrisystem® Desenvolvimento or Nutrisystem® Produção. Additionally water soluble fertilisers were applied by pivot irrigation. These were the SQM VITAS Brazil equivalent of the Ultrasol® brands: Dripsol® Batata Produção, Dripsol® HF Produção (Table 2), Dripsol® NKS, Dripsol® MAP, Dripsol® SOP K+ .

Table 4. Comparison of N:K2O ration per crop stage between the SQM Vitas nutritional programme and farmers practice (FP).

After harvest, the distribution of tubers over the different size classes was assessed. Definition of quality classes in Brazil is dependent on the caliber of the tuber and incidence of defects (diseases or shape), but varies with cultivar, time of harvest and market.

To facilitate comparison between the trials, these were reclassified for this IQ issue, according to the price range received for each quality (Figure 5). The unit of yield in Brazil is the number of bags/ha, with 1 bag containing 50 kg.

Figure 4. Fifteen percent higher yield of well-developed tubers as result of the improved percentage of N-NO3 in the total nitrogen amount, reduced phosphate in base dressing, and elimination of chloride containing fertilizers from the programme (Trial 5).

Table 5. Tuber yield and net revenue analyses. 1 BEP= Break-even point: the number of extra bags of 50 kg/ha required to return investment in SQM VITAS programme, based on the same average price per bag. 2 Net revenue = total revenue-fertilizer cost. Benefit = (net revenue SQM VITAS- net revenue FP)/net revenue FP; 3 Unit of yield = 50 kg bags; 4 Exchange rate 1 USD = 3,7 BRL was assumed.

In any trial, this increase was more than sufficient to return the extra investment in the product, even if in this calculation the price difference for quality was not considered (Table 5).

CROP STAGES: I = Planting, II = Hilling, III=Tuber formation, IV = Tuber bulking

Figure 5. Potassium (K2O/ha) applied in each crop stage follows the requirement of the crop in the SQM Vitas programme, in contrast to the conventional farmers practice.

Results Highlights

Rational use of high quality fertilizers, proposed by SQM VITAS, together with delivery of matching NPK formulae and technical guidance for application was successful for delivery of nutrients at the right time and in the exact amount required by the plants (Tables 3 and 4, Figure 5). Application of the SQM VITAS programme resulted in a higher yield in each of the 5 trials, increasing total yield with 8-15%: a difference of 47-108 bags, or 2,3-5,4 MT/ha compared to the farmers practice (Table 5).

The farmer’s net revenue increased even more by an equally consistent increase in tuber size. For comparison between the trials, size defined classes like “Extra”, “Especial”, “Primeira”, “Pirulito”, were grouped for each trial, based on the price the grower received for the category at the moment of harvest (USD/bag of 50 kg) (Figure 6). Using the SQM VITAS programme, 77-88% of the total yield received premium price in trials 1-4, and this percentage was always higher compared to the farmers practice. Average price received by the grower - calculated from the total yield of tubers in each size class –was higher for the SQM VITAS-treated fields (Table 5). Averaged over all trials, 20% more premium priced produce (+2,3 MT/ha) was harvested.

Figure 6. Distribution of quality classes over the total yield of potatoes after application of the SQM VITAS nutrient programme, or the farmers practice (FP). Price category I: "Extra, Especial" (12-18 USD/bag). Price category II: "Primeira, Segunda" (5-7 USD/bag), Price category III: "Diversas, Pirulito" (2,4-4 USD/bag), Price category IV: "Diversas, Pirulito" (<2,5 USD/bag).

What's next?

With these results at hand, the next steps of SQM VITAS will serve to further develop the market for potassium nitrate in potato:

• Implement side dressing nutrition through pivot irrigation for each phenological stage,

• Expand the recommended nutritional programme with the same farmers that conducted field trials during season

2018/2019,

• Explore agronomical and economical results as consistent arguments for presentations and seminars in order to reach potential regions and farmers.

• Increase the number of applications of potassium nitrate during tuber filling for higher yield (fresh market) and dry matter content (processing industry),

• Promote additional phosphorous applications during vegetative growth through wsNPK instead of high granular fertilizer dosage in base dressing,